English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Glass Coating Production Line

Zhaoqing Kerun Vacuum Equipment Co. , Ltd as a professional glass coating production line manufacturer and glass coating production line supplier in China. Glass coating is a chemical polymer material. Because of its high-density chemical properties, it is used in the field of automotive beauty. At the same time, glass coating has the characteristics of high gloss, anti-oxidation, acid and alkali resistance, and ultraviolet resistance. After coating the paint surface, the gloss of the paint surface is very good, and the paint surface is isolated from the outside world, which plays a good protective role.

Glass Coating Production Line Made in China can be bought with Low Price from Kerun, which is a professional high quality Glass Coating Production Manufacturers and Factory in China. We provide Customized Products service. If you want Pricelist and Quotation, you can ask us by leaving a message. We will get back to you as soon as possible.

- View as

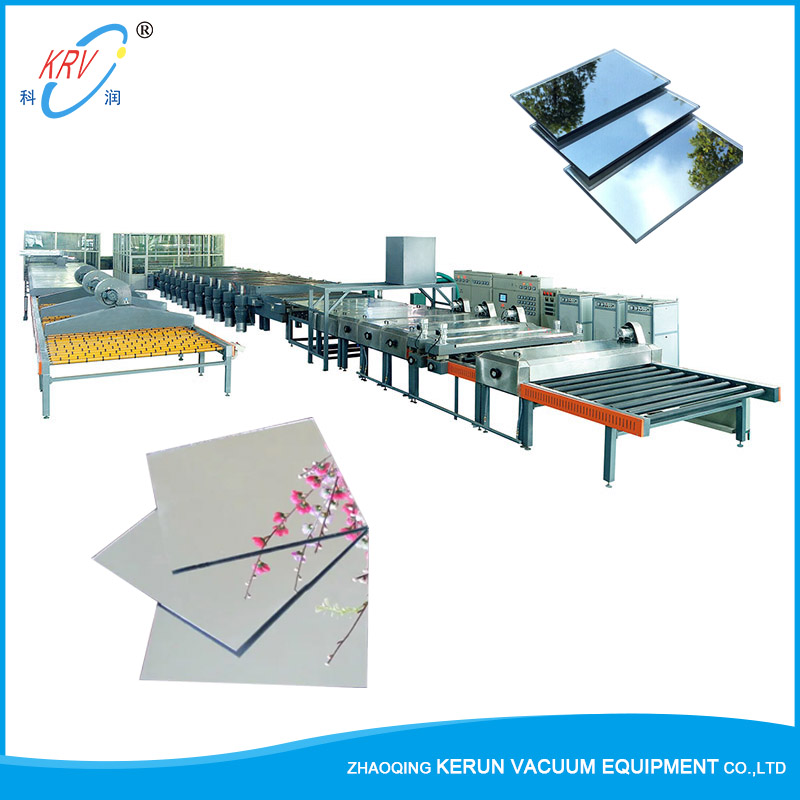

Aluminum Mirror Vacuum Coating Production Line

Aluminum mirror vacuum coating production line maximum glass size : 3600 x 2440mm or 2 pieces of 2440x1830mm . which has the advantages of no aluminum spots, no trachoma, high output, and labor saving. And widely used in the High-class silver mirror production line with complete set of technology. The company has the advanced international level of high-grade silver-mirror glasscoating line and the market share reaches more than 90% in Chinese market. Moreover,theequipment has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.

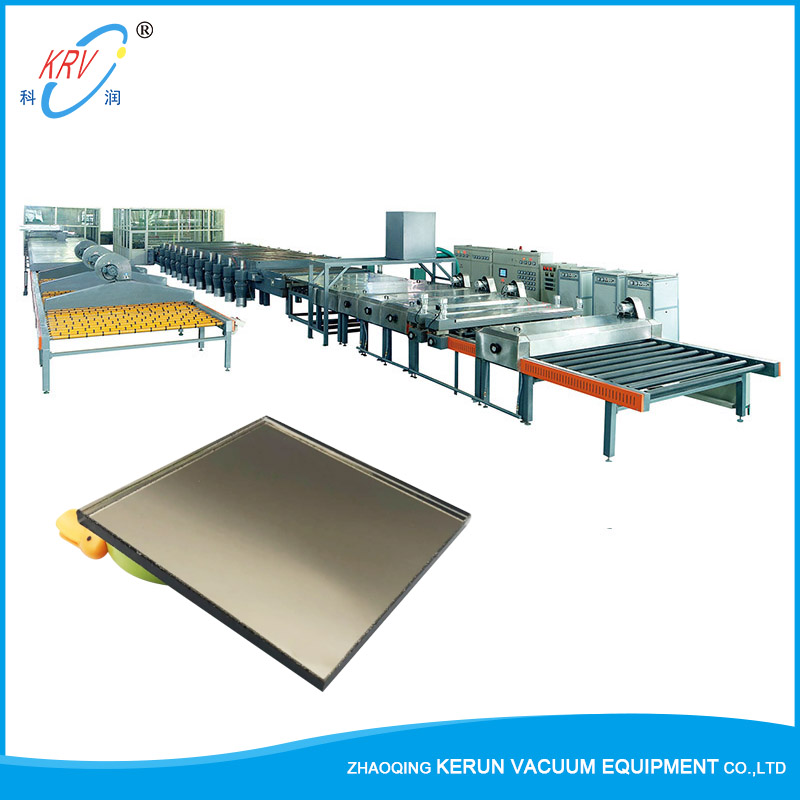

Read MoreSend InquiryLarge-scale Environmental Protection Aluminum Mirror Equipment

Large-scale environmental protection aluminum mirror equipment is efficient, environmentally friendly and energy-saving, and the products are widely used in the construction industry. We have a top R&D team and Independent intellectual property. The company has collected outstanding personneland talents that have more than 30 years of experience in designing and manufacturing ofvacuum equipments as well as rich experience in coating field.

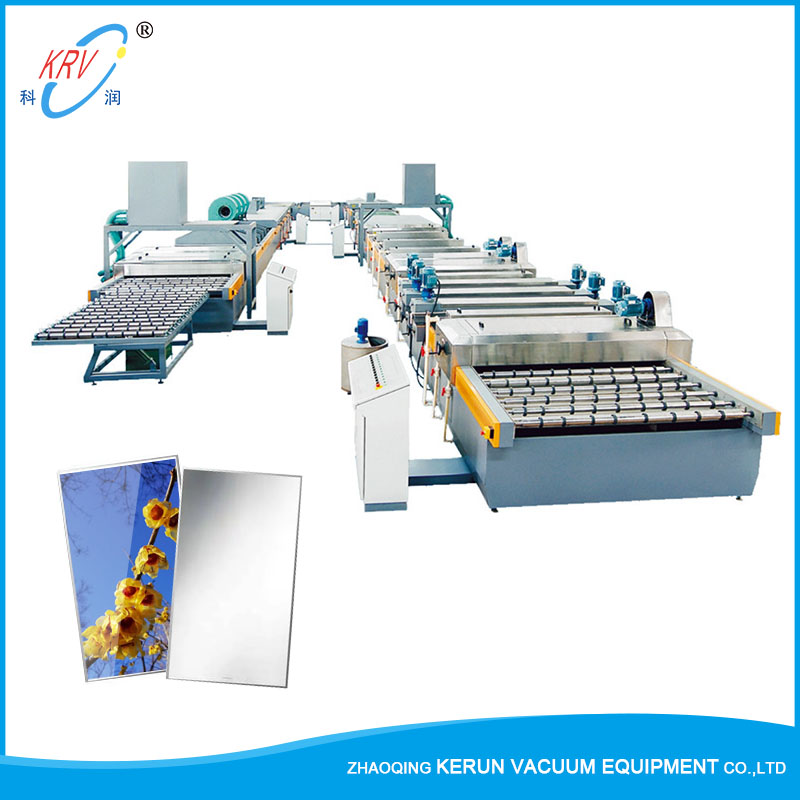

Read MoreSend InquiryLarge-scale Environmental Protection Aluminum Mirror Production Line

Large-scale environmental protection aluminum mirror production line With double-end structure, multi-chamber and multi-sputtering target configuration, all processing including glass washing , coating , flow painting , drying and air-cooling can be finished at one time with high efficiency and lower labor cost. dopts fully automatic control system to ensure production safety and stable quality . The Leading aluminum mirror production line manufacturer in China.

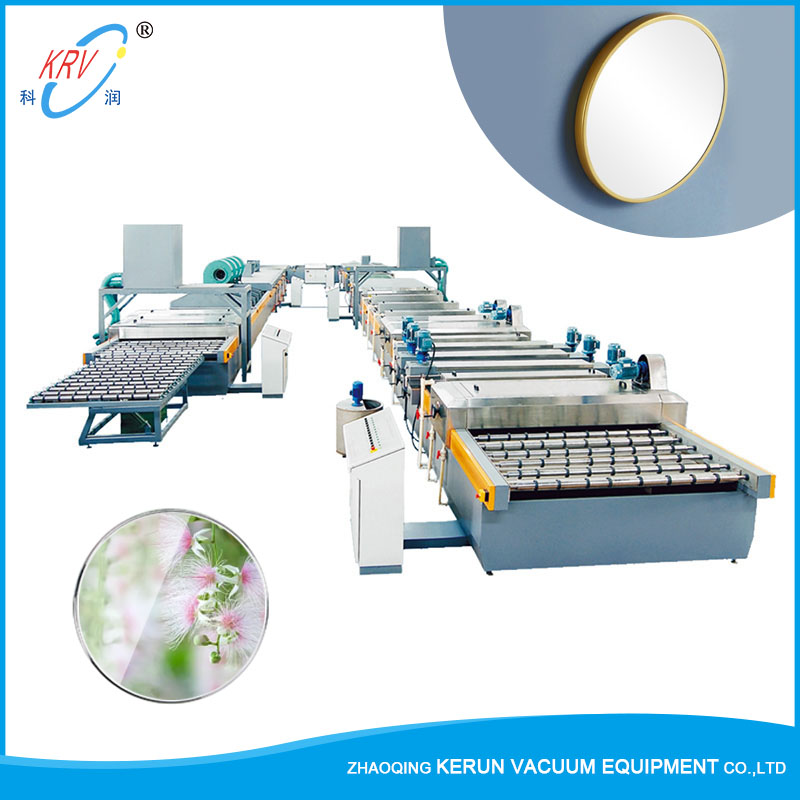

Read MoreSend InquiryHigh-grade Environmental Protection Copper-free Silver Mirror Equipment

Products from high-grade environmental protection copper-free silver mirror equipment can meet European CE standards,and silver mirror products are widely used in the construction industry. The whole production line adopts frequency conversion motor drive and running speed can be adjusted on color display screen.

Read MoreSend InquiryHigh-grade Environmental Protection Copper-free Silver Mirror Production Line

High-grade environmental protection copper-free silver mirror production line adopt chemical spraying method to plate the glass surface with silver film, passivation protection, and then paint one or two layers of paint film. adopt quartz infrared heating tube for oven drying. size and configuration can be customized according to customer requirements

Read MoreSend InquiryHigh-grade Silver Mirror Production Line

The high-grade silver mirror production line from the glass loading, then to glass washing, silver plating, copper plating, painting, baking, repainting, baking, washing, mark printing, and testing, finish in one time, the silver mirror can be packed after unloading. It is driven by a variable frequency speed regulation motor, and the running speed can be adjusted from the color display. The Leading silver mirror production line manufacturer in China.

Read MoreSend Inquiry