English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

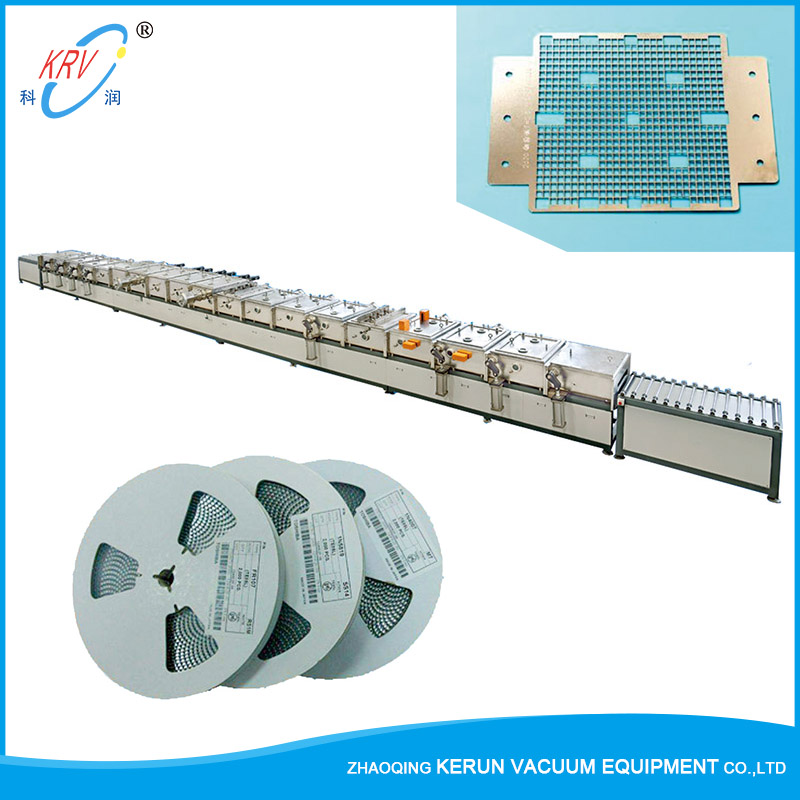

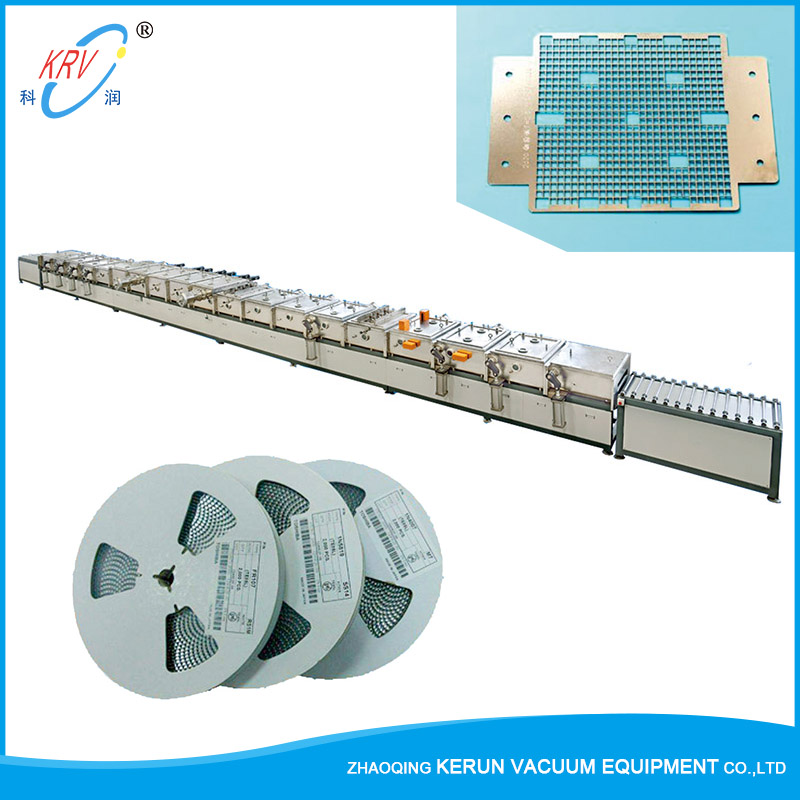

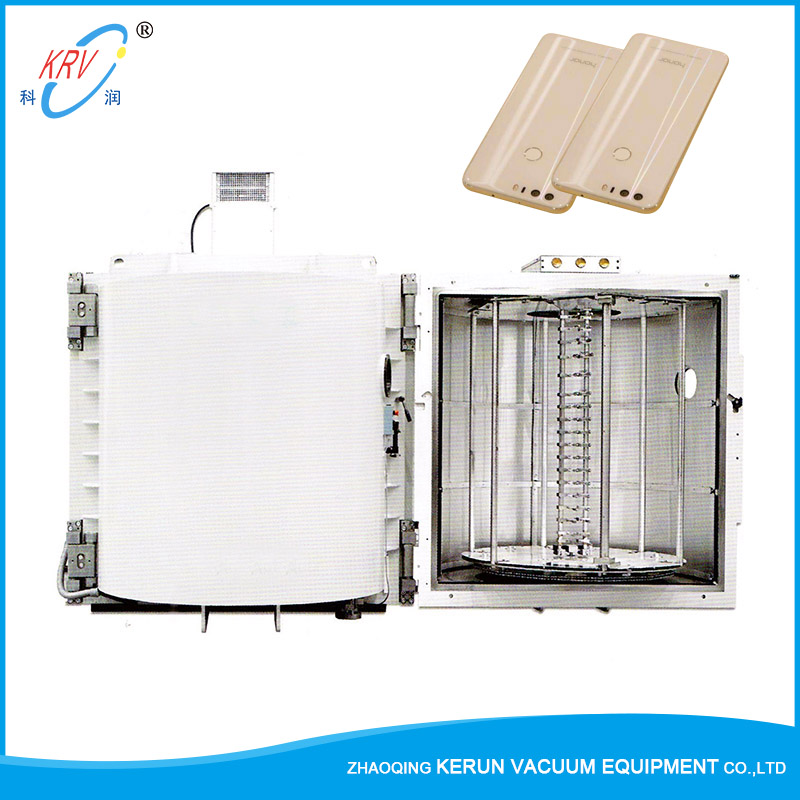

Magnetic Core Inductance Coating Production Line

The Magnetic core inductance coating production line greatly improves the bonding force and adhesion between the film layer and the workpiece uses magnetic sputtering to coat the surface of the magnetic core inductance with NI, AG, SN, CU and other materials, which are used as inductance lead welding. he whole process of the magnetic core inductance coating machine has no waste gas, no waste water discharge, and meets the national industrial requirements.

Send Inquiry

Magnetic Core Inductance Coating Production Line

The magnetic core inductance coating production line adopts the method of magnetic sputtering to coat the surface of the magnetic core inductance with NI, AG, SN, CU and other materials, which is used as the inductance lead welding. The advanced production technology greatly improves the bonding force and adhesion between the film layer and the workpiece, and ensures the consistency and stability of the product. The whole process has no waste gas, no waste water discharge, which meets the national industry requirements.

We assure you of our high quality services at all time. Magnetic Core Inductance Coating Production Line is widely used in all kinds of high-grade and a variety of personalized decoration, Self-direction control of life, advocate to enjoy work, enjoy life, advocate annotation quality, more cutting-edge, more publicity, more exceptions, more quality.

1.Product Introduction

2.Product Parameter (Specification)

The magnetic core inductance coating production line greatly improves the bonding force and adhesion between the coating and the workpiece

3.Product Feature And Application

The whole process of the magnetic core inductance coating production line has no waste gas and no waste water discharge, which meets the national industrial requirements.

4.Product Details

The size and configuration of the magnetic core inductance coating production line can be customized according to customer requirements

5.Product Qualification

The products from the magnetic core inductance coating production line can meet the European CE standard

6.Deliver,Shipping And Serving

We have a top R&D team, cooperate with our superb manufacturing team, professional sales team and dedicated service team to jointly provide customers with high-tech, high-quality products and efficient, convenient and comprehensive pre-sales and after-sales professional services.