English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

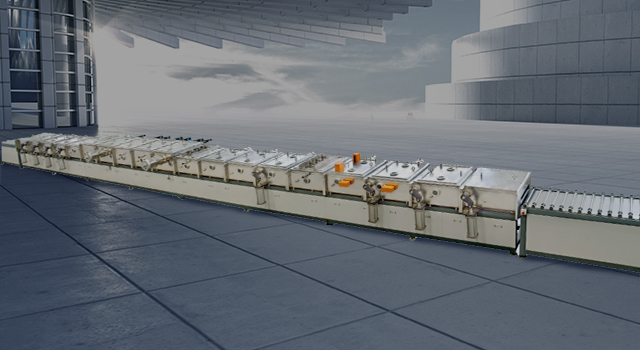

Energy Industry: Solar photovoltaic cell TCO coating series equipment

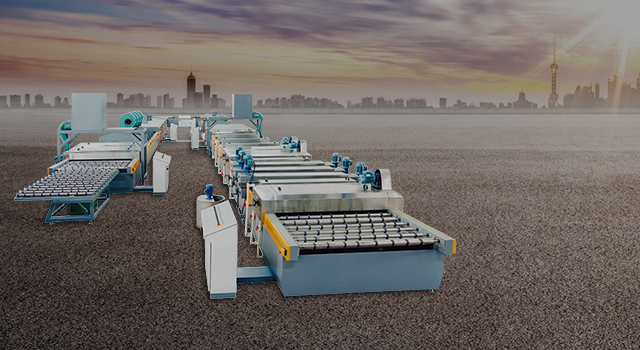

Construction Industry: Offline sunlight control coated glass series equipment

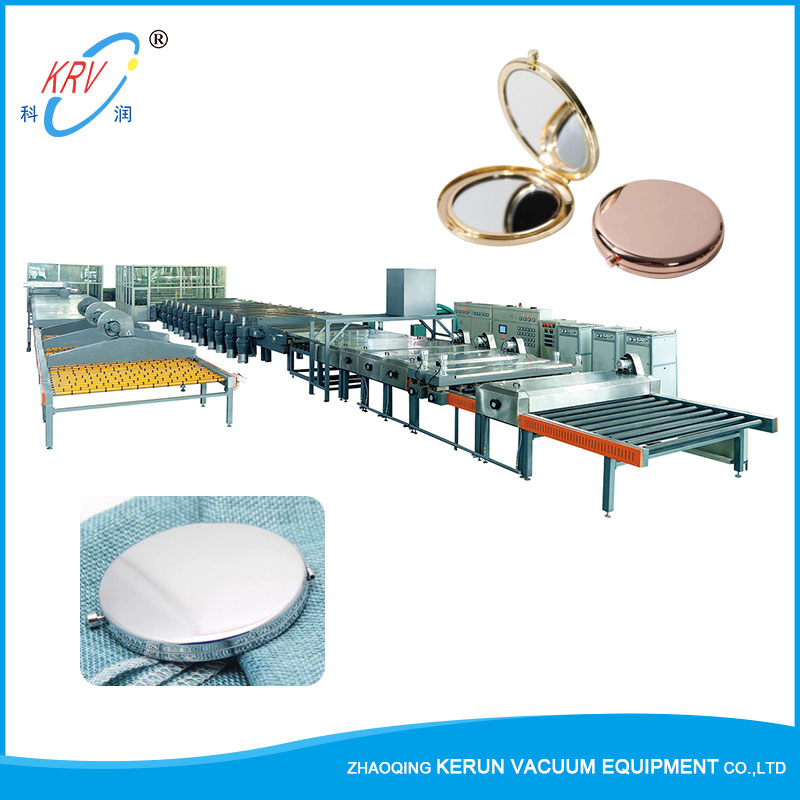

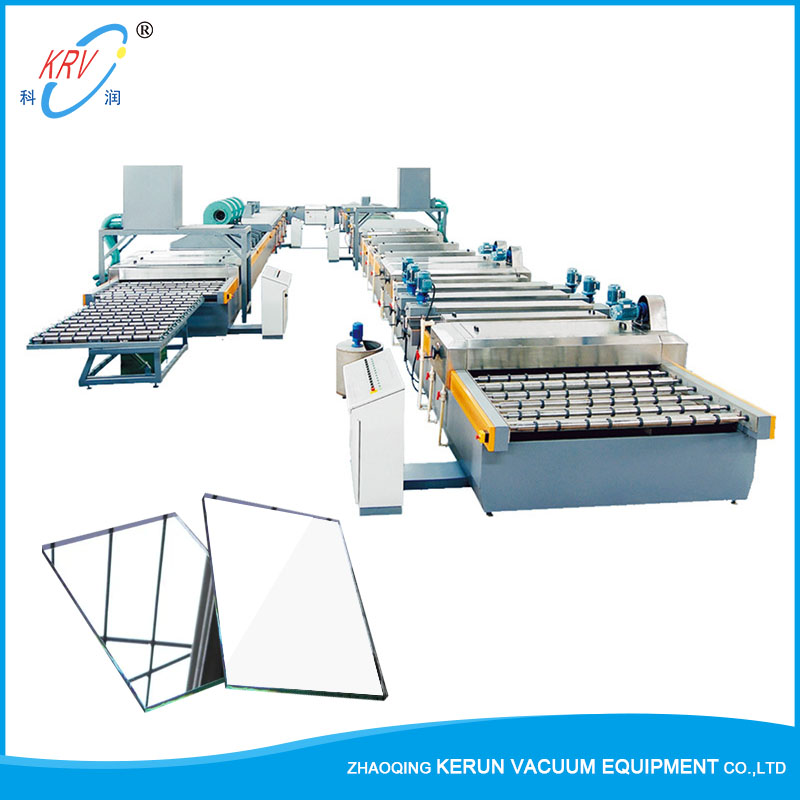

Automotive Industry: Full production line of car rearview mirror

Automotive lamp head interior decoration coating equipment

Molybdenum aluminum molybdenum capacitive screen glass coating equipment

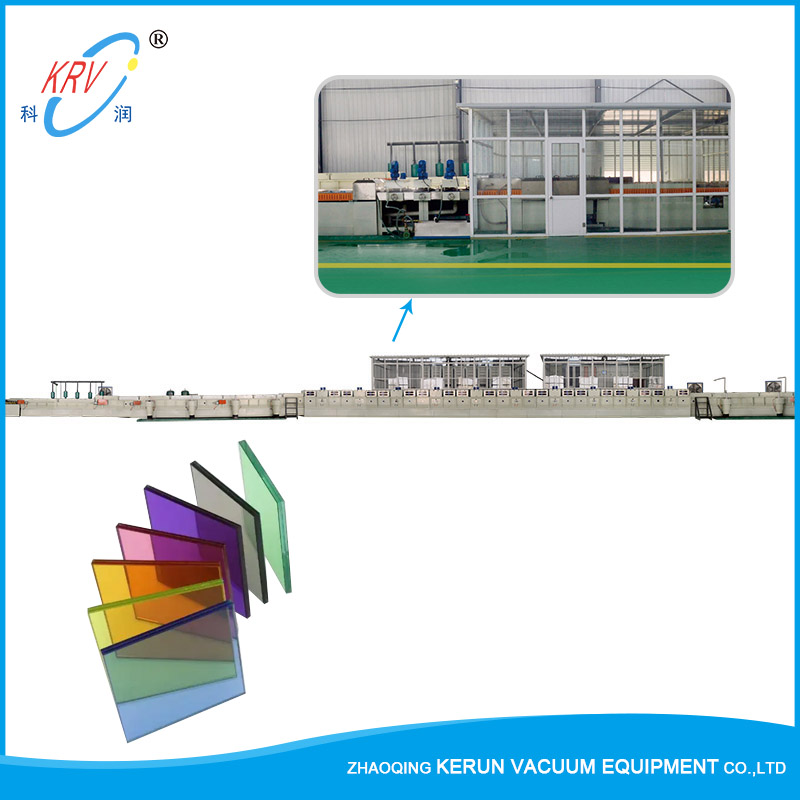

High-grade environmentally friendly silver mirror production line and a full set of technology

Color mirror production line and complete production technology

Mobile phone panel coating equipment and a full set of technologies

In modern manufacturing, achieving uniform thin-film coatings is critical for product quality and efficiency. I often ask myself: how can my production lines benefit from advanced coating technology? The answer lies in the Winding-type Vacuum Coating Equipment. This equipment allows continuous mater...

DetailsIt is a process of depositing materials onto a substrate surface using physical or chemical methods in a low-pressure environment to form a thin film. Through this technology, high-purity and high-precision thin film deposition can be achieved, giving it specific optical, electrical, mechanical and ...

DetailsVacuum ion plating equipment is a device that uses a high-voltage electric field to accelerate ion beams and make them hit the surface of an object, thereby forming a thin film. Its working principle can be divided into three parts, namely vacuum system, ion source and target.

DetailsWith the advancement of science and technology, automatic vacuum coating equipment has become an indispensable part in various fields. Its widespread use enables people to process various metal and non-metal materials more efficiently in production. Although different types of automatic vacuum coati...

Details

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.