English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Products

- View as

Auto Lamp Protective Film Coating Equipment

Auto lamp protective film coating equipment has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far. The equipment is a special vacuum coating equipment solution for the auto lamp protective film, and has been applied in many auto lamp factories. We assure you of our high quality services at all time.

Read MoreSend InquiryMagnetic Core Inductance Coating Machine

The magnetic core inductance coating used as inductance lead welding. The advanced production process greatly improves the bonding force and adhesion between the film layer and the workpiece.The products from the magnetic core inductance coating machine can meet the European CE standard. The product core inductance coating production line has no waste gas and no waste water discharge, which meets the national industrial requirements.

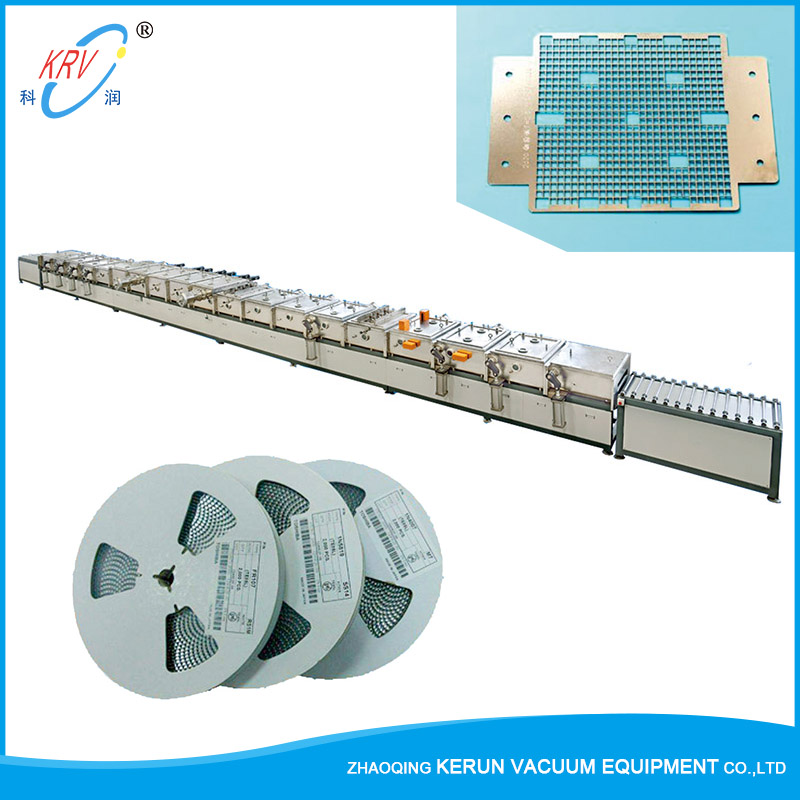

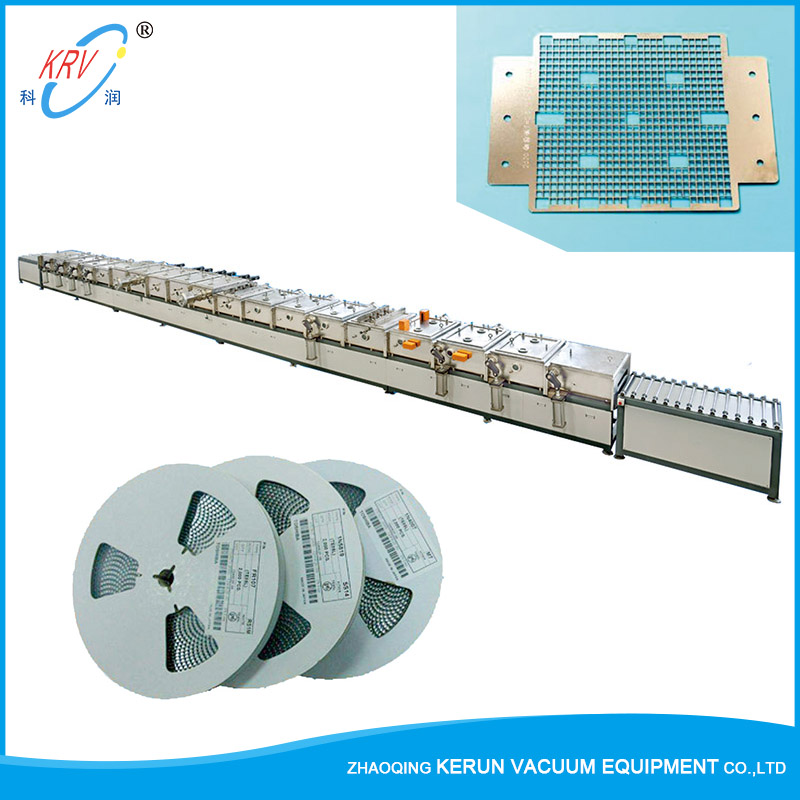

Read MoreSend InquiryMagnetic Core Inductance Coating Production Line

The Magnetic core inductance coating production line greatly improves the bonding force and adhesion between the film layer and the workpiece uses magnetic sputtering to coat the surface of the magnetic core inductance with NI, AG, SN, CU and other materials, which are used as inductance lead welding. he whole process of the magnetic core inductance coating machine has no waste gas, no waste water discharge, and meets the national industrial requirements.

Read MoreSend InquiryElectronic Components Magnetic Sputtering Production Line

Electronic components magnetic sputtering production line uses the magnetic sputtering coating process for coating. According to the process requirements, nickel, chromium, alloy, aluminum and other metal film layers are available. widely used in electronic products such as mobile phones, electronics, audio, home appliances and other industries. We have a top R&D team, cooperate with our superb manufacturing team, professional sales team and dedicated service team to jointly provide customers with high-tech.

Read MoreSend InquiryChip Resistance Terminal Magnetic Sputtering Coating Machine

Chip resistance Terminal Magnetic Sputtering Coating Machine the double magnetron sputtering target has high coating rate and dense film. Is a special equipment for chip resistance end coating. The coating yield is over 99%. The size and configuration an be customized according to customer requirements.

Read MoreSend InquiryHousehold Appliance Glass Magnetron Coating Production Line

Household appliance glass magnetron coating production line adopts magnetron sputtering coating process to coat the glass. This production line is widely used in the glass surface coating of household appliances such as microwave ovens, disinfection cabinets, range hoods, stoves, refrigerators, air conditioners, etc. coating glass color diversification.The products from the household appliance glass magnetic coating production line can meet the European CE standard.

Read MoreSend Inquiry