English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Vacuum Coating Machine for Plastic Manufacturers

Welcome to buy Magnetron Sputtering Coating Machine, Low Coating Production Line, Aluminum Mirror Production Line from Kerun. Our factory is one of the manufacturers and suppliers in China. Welcome new and old customers to continue to cooperate with us to create a better future together!

Hot Products

Multi-arc Magnetic Ion Coating Machine

Multi-arc magnetic ion coating machine uses programmable logic controller (PLC), automatic or manual optional. This series of equipment is mainly suitable for coating the surface of metal parts, hardware, etc. One layer or multi-layer metal film. For example, high-grade decorative films such as TIN film and imitation gold film, gold-doped film, gun black film, etc. Has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.LOW-E Curtain Wall Glass Coating Equipment

We produced LOW-E curtain wall glass coating equipment which can reduce the emissivity of the glass from 0.84 to 0.1 or even lower, and reduce the radiation heat loss 90%. We have a top R&D team, cooperate with our superb manufacturing team Products from the LOW-E curtain wall glass coating equipment can meet European CE standards. The Leading manufacturer in China.Large-scale Environmental Protection Aluminum Mirror Production Line

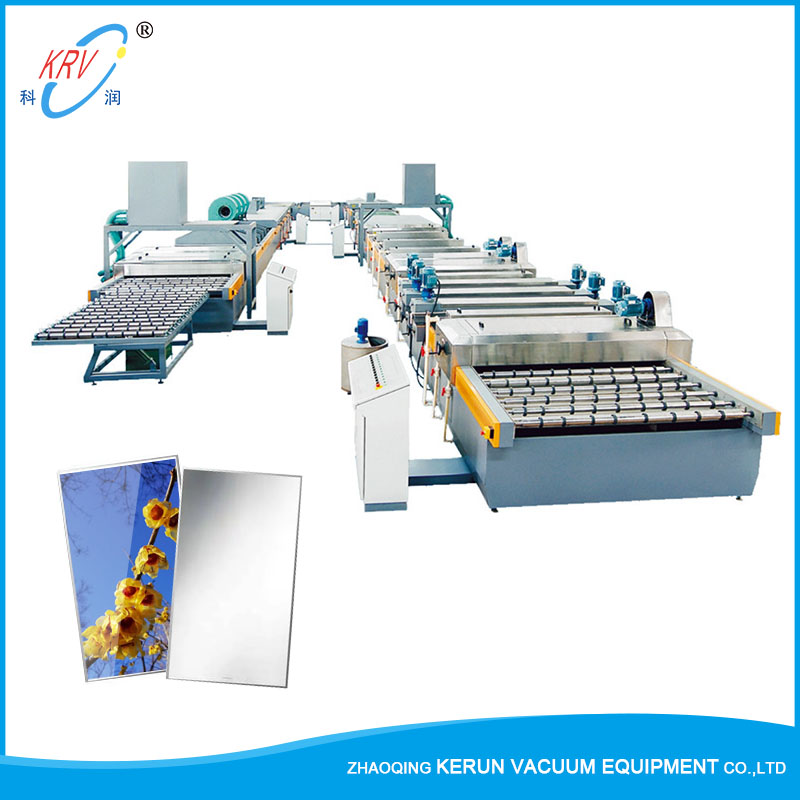

Large-scale environmental protection aluminum mirror production line With double-end structure, multi-chamber and multi-sputtering target configuration, all processing including glass washing , coating , flow painting , drying and air-cooling can be finished at one time with high efficiency and lower labor cost. dopts fully automatic control system to ensure production safety and stable quality . The Leading aluminum mirror production line manufacturer in China.Aluminum Mirror Vacuum Coating Production Line

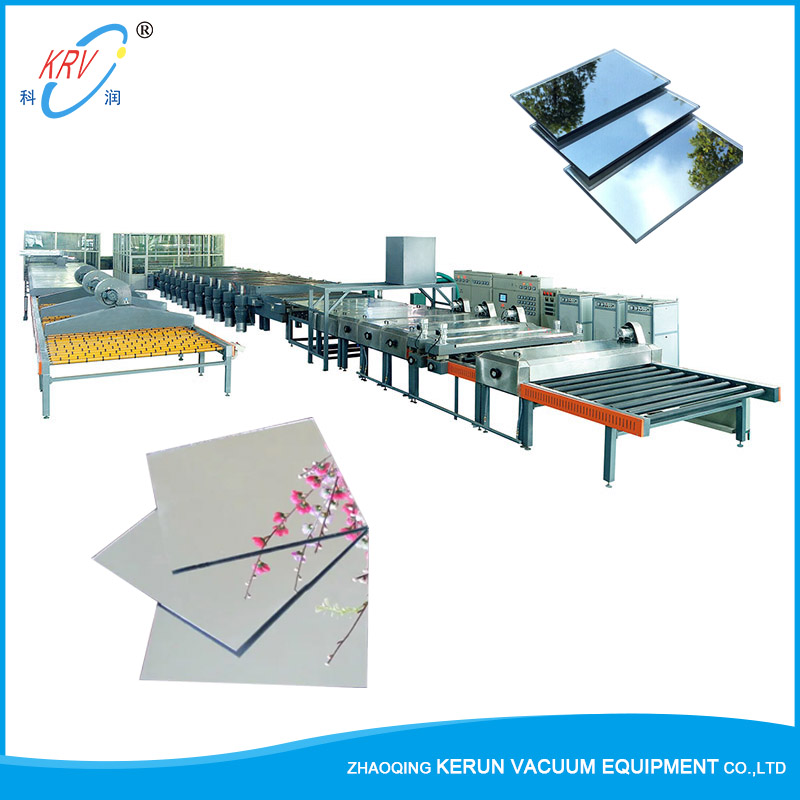

Aluminum mirror vacuum coating production line maximum glass size : 3600 x 2440mm or 2 pieces of 2440x1830mm . which has the advantages of no aluminum spots, no trachoma, high output, and labor saving. And widely used in the High-class silver mirror production line with complete set of technology. The company has the advanced international level of high-grade silver-mirror glasscoating line and the market share reaches more than 90% in Chinese market. Moreover,theequipment has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.High Vacuum Winding Type Coating Equipment

The high vacuum winding type coating equipment is equipped with an efficient vacuum pumping system. The winding system adopts imported all-digital tension control system. The equipment is a special equipment for vacuum evaporation of aluminum film on the surface of film coil. We have a top R&D team and Independent intellectual property. size and configuration can be customized according to customer requirements.Magnetic Core Inductance Coating Machine

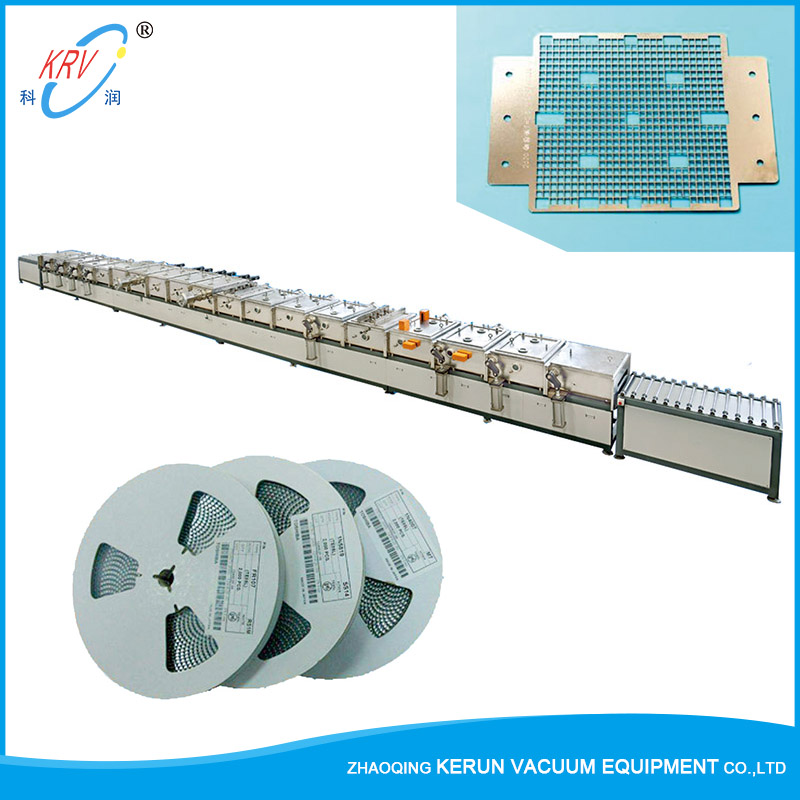

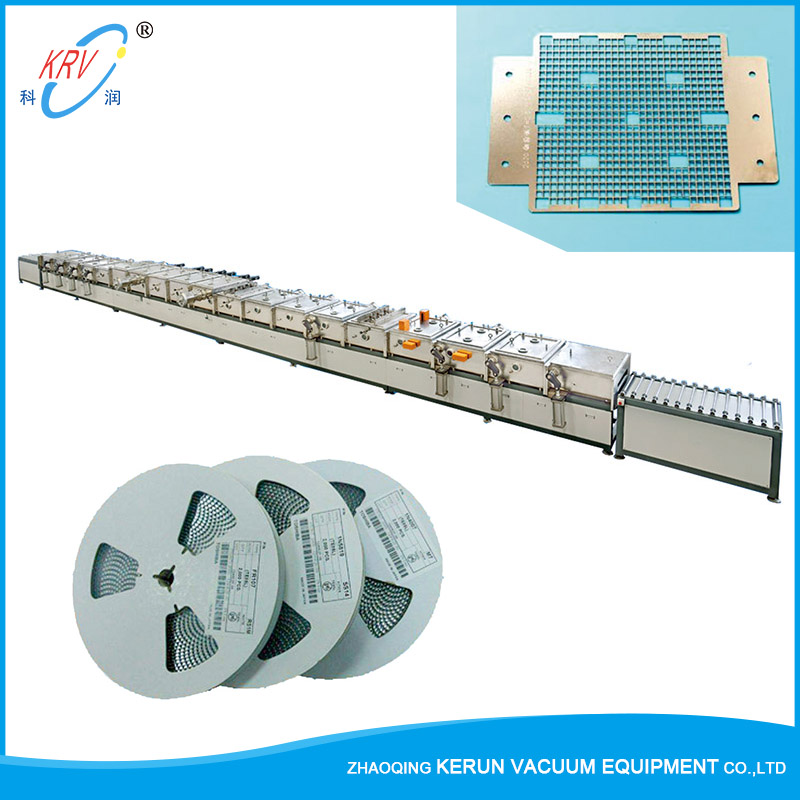

The magnetic core inductance coating used as inductance lead welding. The advanced production process greatly improves the bonding force and adhesion between the film layer and the workpiece.The products from the magnetic core inductance coating machine can meet the European CE standard. The product core inductance coating production line has no waste gas and no waste water discharge, which meets the national industrial requirements.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy